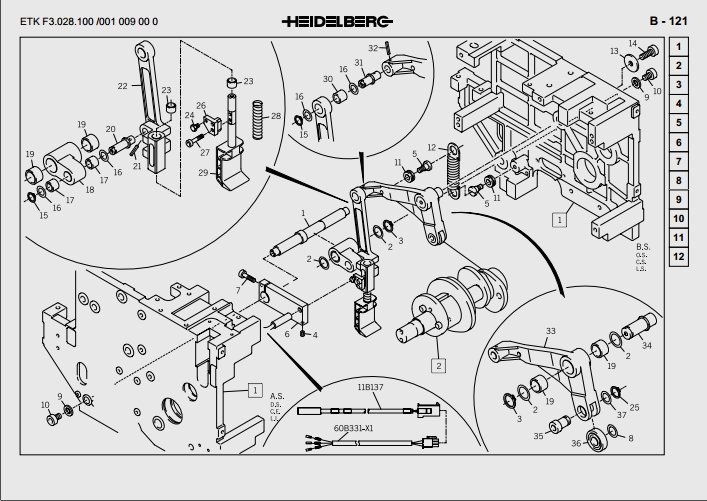

HEIDELBERG GTO 52-2 DI

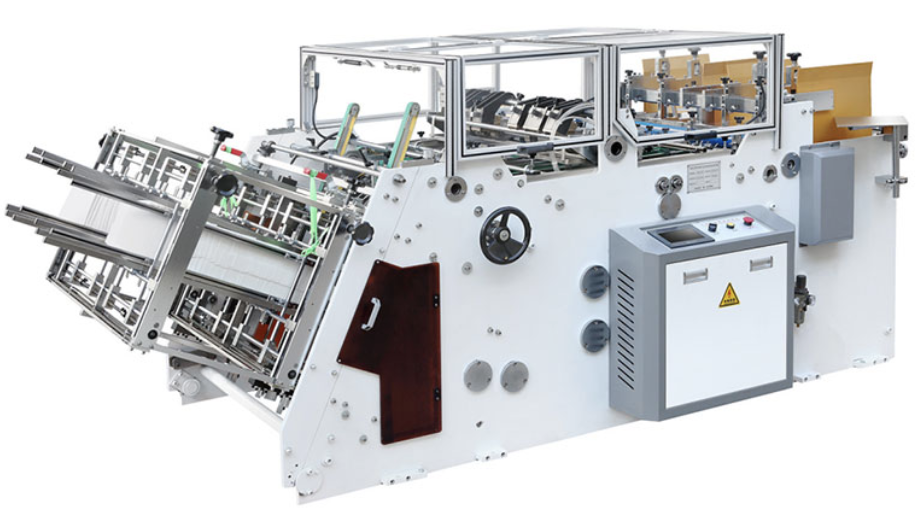

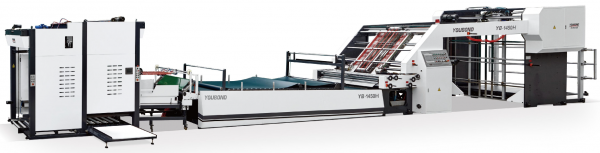

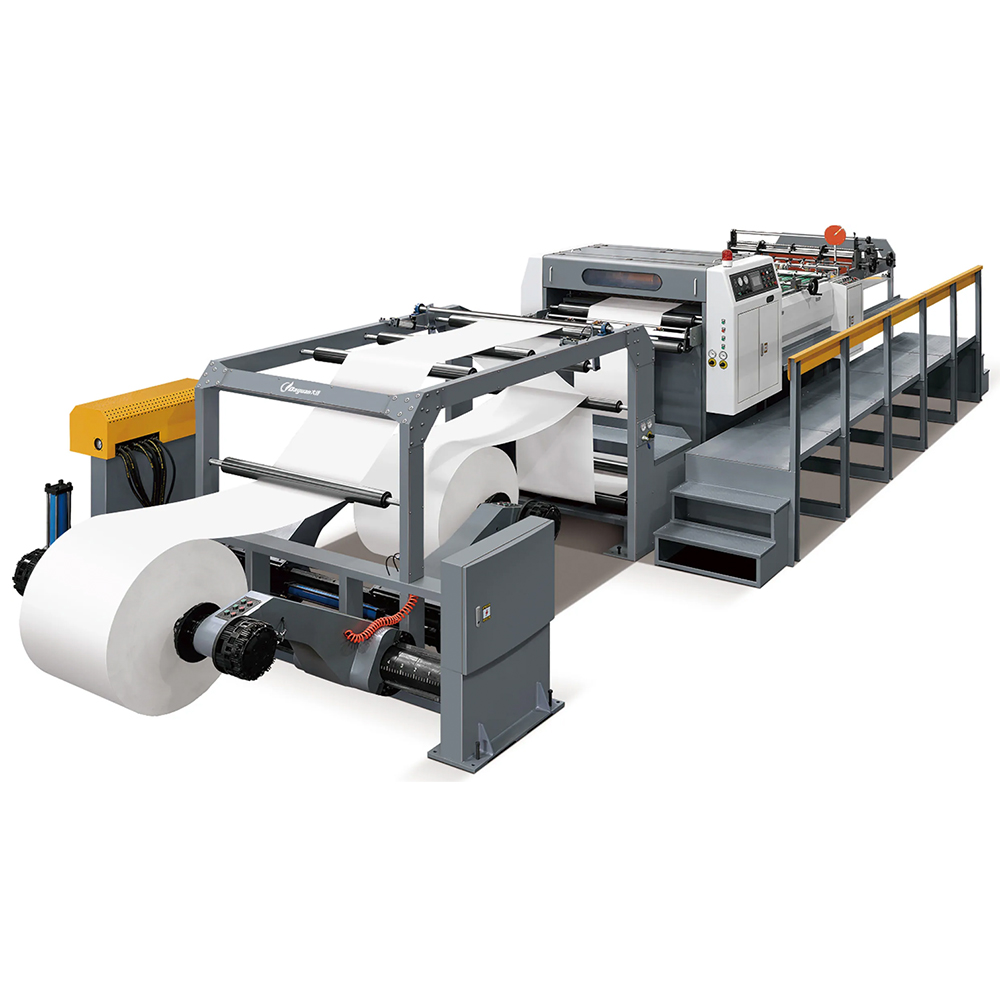

| Waterless Offset Printing The advantages of Waterless Offset printing Heidelberg DI Offset Thanks to waterless offset technology, we achieve excellent performance at higher resolutions and LPI compared to the usual. It reproduces colors that conventional offset machines cannot, on both coated and uncoated papers. What is Waterless Offset Printing? However, this process has one major drawback: water. Despite technological advances reducing the negative effects, the problem persists. With waterless inks and plates, there is no such issue since water is not used at all. This results in “cleaner” prints—both environmentally and in practice. Why without water? Greener Cleaner More Efficient Sharper Images Substrate Options Simpler Smarter |

Description

Additional information

| Availability | Immediately |

|---|---|

| Brand | Heidelberg |

| Condition | Used |

| Model | GTO 52-2 DI |

| Sheet Size | 36×52 cm |

| Status | In production |